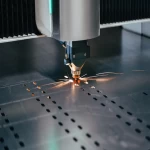

Laser technology is revolutionizing the way products are designed, produced, and customized across industries. From automotive to electronics, and jewelry to medical devices, lasers offer unparalleled precision, speed, and flexibility compared to traditional manufacturing methods.

Key Advantages of Laser Technology in Modern Manufacturing:

-

High Precision & Accuracy: Laser systems can create intricate designs, markings, and cuts with micron-level accuracy.

-

Non-Contact Processing: Minimizes material damage and reduces the risk of wear and tear.

-

Speed & Efficiency: Accelerates production times while maintaining consistent quality.

-

Versatility: Works on a wide range of materials including metals, plastics, ceramics, and glass.

-

Customization & Flexibility: Easily adapts to different product designs and batch sizes.

-

Traceability & Branding: Enables permanent markings such as serial numbers, QR codes, and logos for authentication and quality assurance.

-

Reduced Waste: Laser processing is cleaner and more precise, lowering material wastage.

By integrating laser technology, manufacturers can enhance product quality, reduce operational costs, and stay competitive in a fast-paced market. Whether it’s for cutting, engraving, marking, or welding, lasers are shaping the future of efficient and precise manufacturing.