The automobile industry doesn’t have room for guesswork. It’s complex and demanding, especially when it comes to automobile shock absorbers. They need to be durable, precise, and efficient over the long run to ensure both quality and safety.

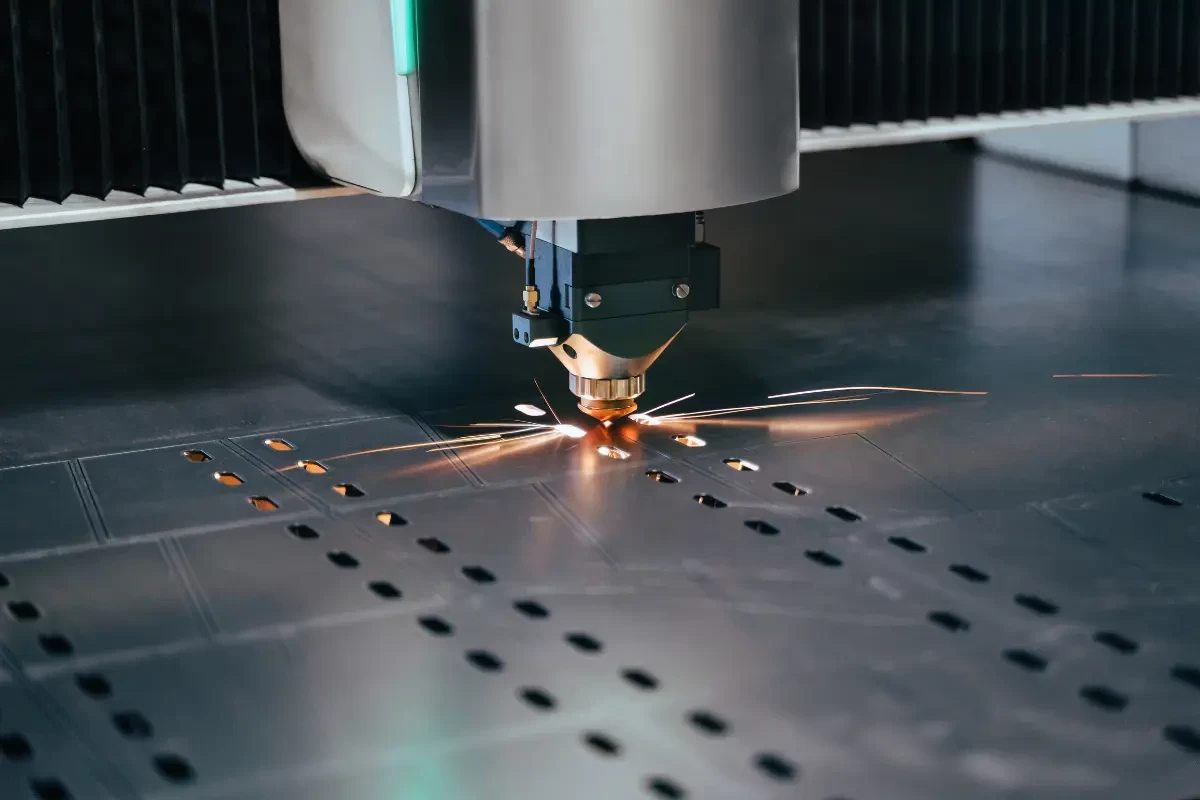

In this blog post, we’ll discuss how fiber laser marking has completely changed this game and why you should choose it. Read on until the end and get all the information you need on Fiber Laser Marking job work

Here’s why and how fiber laser marking has become widely used in the automotive industry:

- How is it used? This machine ensures the metal components are precisely marked, including exhaust systems, gears, and intricate body parts, without causing any distortion.

- Long-lasting: These machines are ideal for creating permanent, durable markings on steel, aluminum, and titanium. They ensure that identification marks on vehicle parts remain intact even under extreme temperatures, exposure to fluids, and abrasion throughout an automobile’s life cycle.

- Traceability: It is highly valued by auto manufacturers for labeling and tracking parts with unique serial numbers, barcodes, or QR codes.

- Speed: This high-speed technology enables mass, automated production lines.

- Anti-counterfeiting: Applying fiber laser marking is crucial to prevent parts counterfeiting, protect brand reputation, and ensure buyer safety.