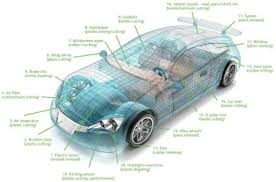

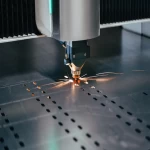

Laser marking technology has become an essential tool in the automotive industry, where precision, durability, and traceability are critical. From engine components to chassis parts, laser marking provides permanent and high-quality identification without compromising the integrity of the material.

Key Advantages of Laser Marking in Automotive Applications:

-

Durable Identification: Marks resist heat, abrasion, and corrosion, ensuring long-lasting part identification.

-

Traceability: Helps track parts throughout the supply chain, essential for recalls and quality control.

-

High Precision: Engraves serial numbers, barcodes, QR codes, and logos with accuracy.

-

Non-Contact Process: Minimizes risk of material deformation or damage during marking.

-

Efficiency: Rapid marking improves production speed and reduces downtime.

-

Compliance: Meets automotive industry standards for part marking and traceability.

With laser marking, automotive manufacturers can enhance product safety, ensure quality assurance, and maintain reliable records for each component. This technology is transforming the way the industry handles part identification, branding, and quality management.