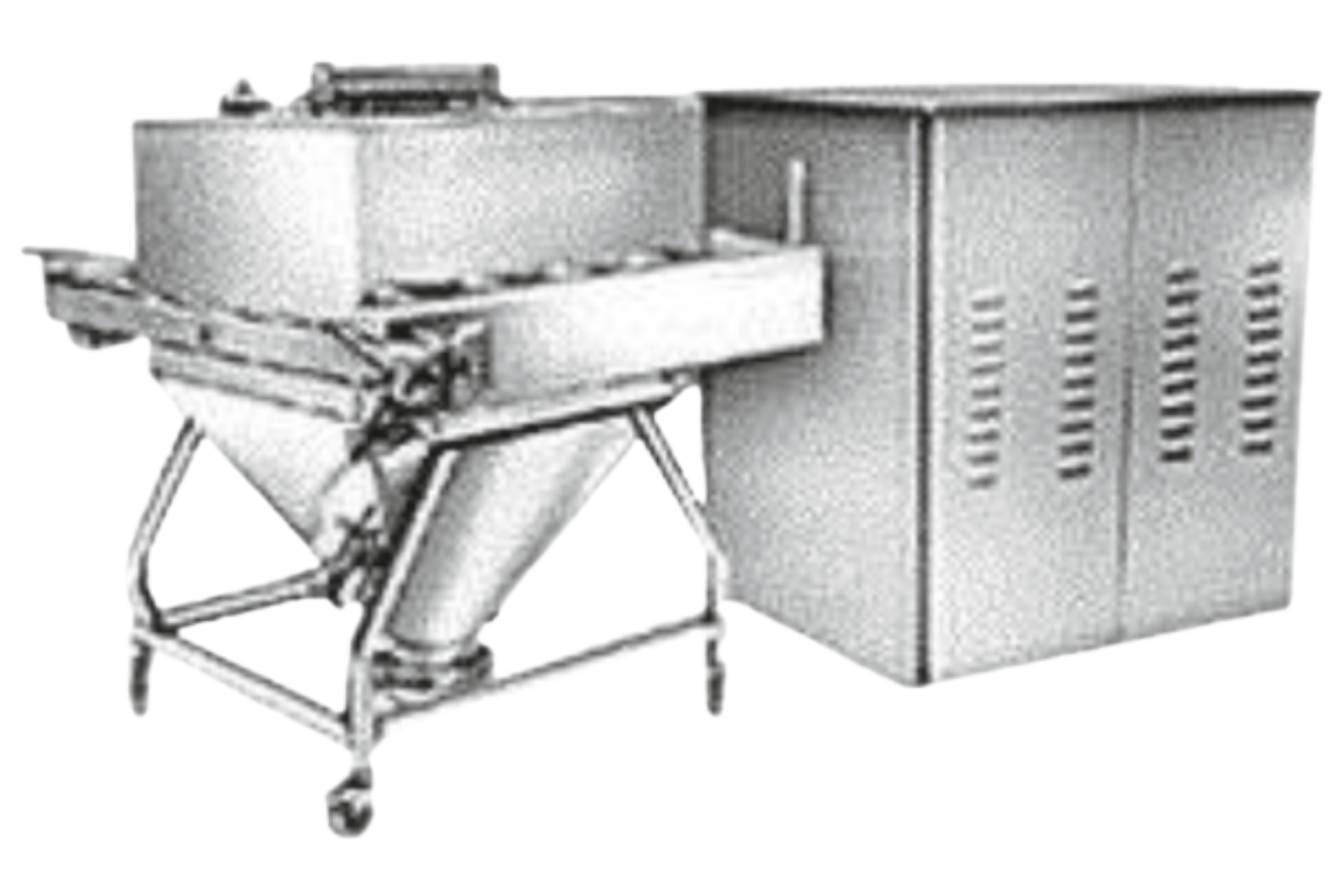

CONTA BLENDER

Available in 5 kgs. to 600 kgs.

For Uniformity in Mixing of Dry Powder & Granules.

Contact parts SS 316 & Non Contact parts SS 304.

Conta Blender (Pharmaceutical Grade)

A Conta Blender is a closed, dust-free mixing system widely used in the pharmaceutical, chemical, and food industries for uniform blending of powders and granules, especially where containment and operator safety are critical.

🔧 Specifications (Standard / Typical)

⚙️ General Details

Equipment Type: Conta Blender / Containment Blender

Application: Dry powder & granule mixing

Design: Closed & dust-tight system

Mixing Principle: Tumbling / Bin rotation

📏 Capacity

Working Volume: 50 L to 2500 L (customizable)

Fill Volume: 60–80% of total bin capacity

🧱 Construction

Product Contact Parts:

SS 316 / SS 316L

Non-Contact Parts:

SS 304

Surface Finish:

Internal: ≤ 0.4–0.6 µm (mirror / electro-polished optional)

External: Matt / polished

🔄 Drive & Operation

Motor: Flameproof / Non-flameproof

Speed: 3–15 RPM (VFD controlled)

Transmission: Gearbox / Chain drive

Rotation: Bi-directional (optional)

🔐 Containment & Safety

Dust-Free Operation: Yes

Closed Charging & Discharging: Yes

Interlock Safety System: Provided

Emergency Stop: Yes

OEL Level: Can meet low OEL requirements (with proper configuration)

🧼 Cleaning

Cleaning Method:

Manual

CIP (Clean-in-Place) – Optional

Quick Dismantling: Yes

🔌 Electricals

Power Supply: 415V / 50 Hz / 3 Phase

Control Panel:

Push button / PLC / HMI (optional)

Compliance: GMP / cGMP

🏭 Optional Features

Bin lifting system

Vacuum transfer interface

Load cell integration

Nitrogen purging

Explosion-proof design (ATEX compliant)

🏥 Applications

Pharmaceutical formulations

API & bulk drug blending

Nutraceutical powders

Chemical & fine chemicals