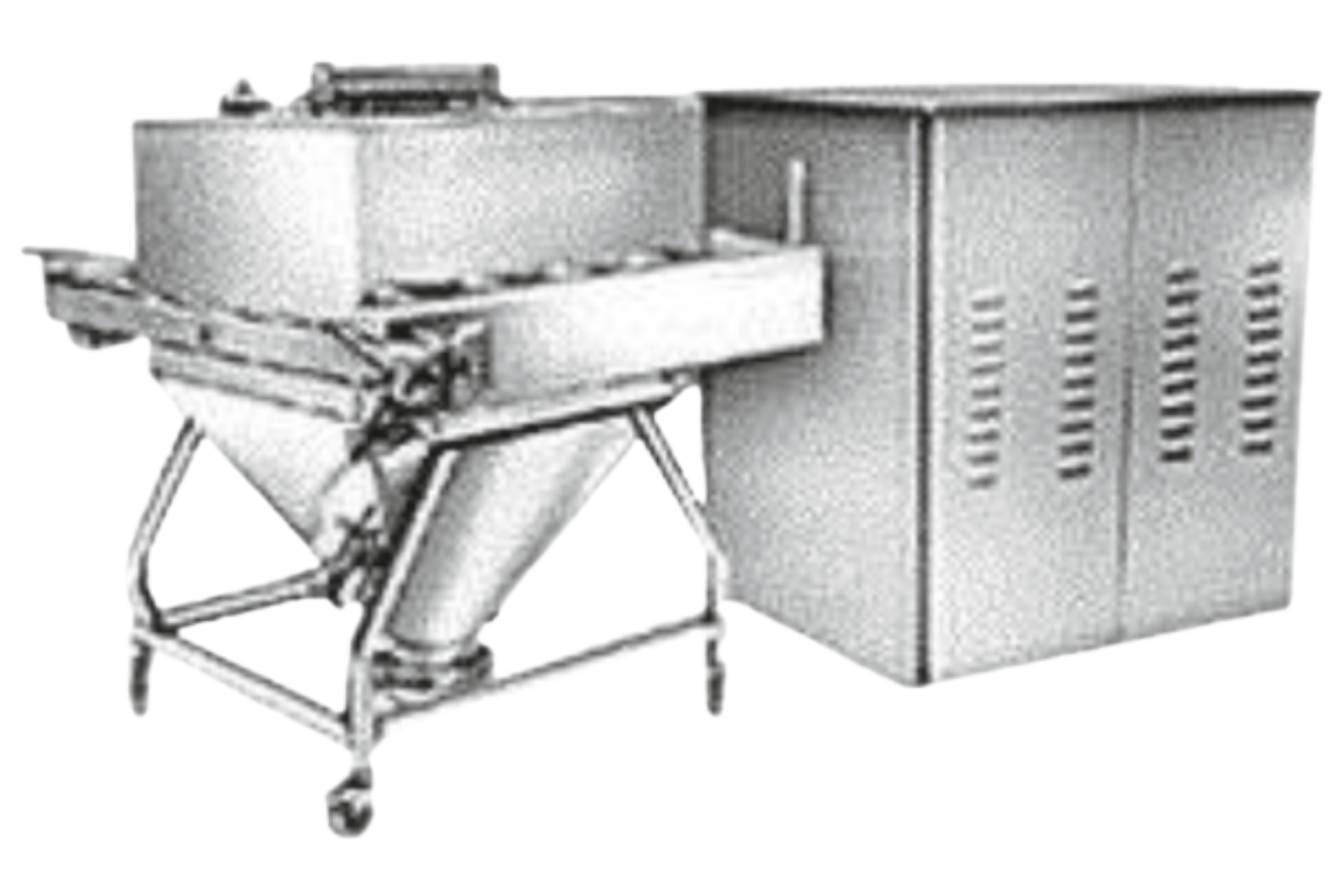

OCTOGONAL BLENDER

Octogonal Blender with Bin Charging System.

Model 250 to 5000 Lts.

Available STD/GMP Model.

Contact parts SS 316 & Non Contact parts SS 304.

Available Pneumatic Trolley for Container.

For Uniform Mixing of Dry Powder and Granules.

Pneumatic charging available.

VFD & Flameproof. (Optional)

🔍 What an Octagonal Blender Is

An Octagonal Blender is a slow-tumbling industrial machine used to homogeneously blend dry powders and granules (common in pharmaceutical, food, chemical, and cosmetic industries). Its octagon-shaped drum promotes gentle, efficient mixing with minimal degradation of particles.

It tumbles contents slowly so materials cascade through all octagon sides.

Shape and motion encourage thorough mixing with low RPM and gentle action.

Often built with stainless steel contact parts for hygiene & easy cleaning.

📊 Typical Specifications (Examples)

Specifications vary by model and manufacturer, but here’s a sense of common features and capacities:

⚙️ Standard Technical Specs (Example Models)

| Model / Capacity | Gross / Working Volume | RPM Range | Motor | Discharge |

|---|---|---|---|---|

| OCB 100 | 100 L / 60 L | 5–22 | ~1.5 HP | 3″–4″ |

| OCB 200 | 200 L / 120 L | 2–16 | ~2 HP | 4″–6″ |

| OCB 500 | 500 L / 300 L | 2–12 | ~3 HP | 6″–8″ |

| OCB 1000 | 1000 L / 600 L | 1–8 | ~5 HP | 8″–10″ |

| OCB 1500 / 2000 | 1500–2000 L Range | ~1–6 | 7.5–10 HP | 10″–12″ |

(Values are representative from manufacturer ranges; details may vary by maker and model.)

🧰 Common Features

✅ Octagonal Vessel Shape – promotes material flow from all sides

✅ Low RPM Slow Mixing – gentle on particles, prevents damage

✅ Stainless Steel Construction – SS304/SS316 contact parts

✅ Butterfly Valve at Discharge – for controlled emptying

✅ Bin or Vacuum Charging – optional dust-free material loading

✅ Easy Cleaning & GMP Design – smooth surfaces, removable baffles

🛠 Typical Applications

Pharmaceuticals – dry powder & granule mixing

Food – spice, flour, additive blending

Chemicals – powders & particulate materials

Cosmetics – granular mix products