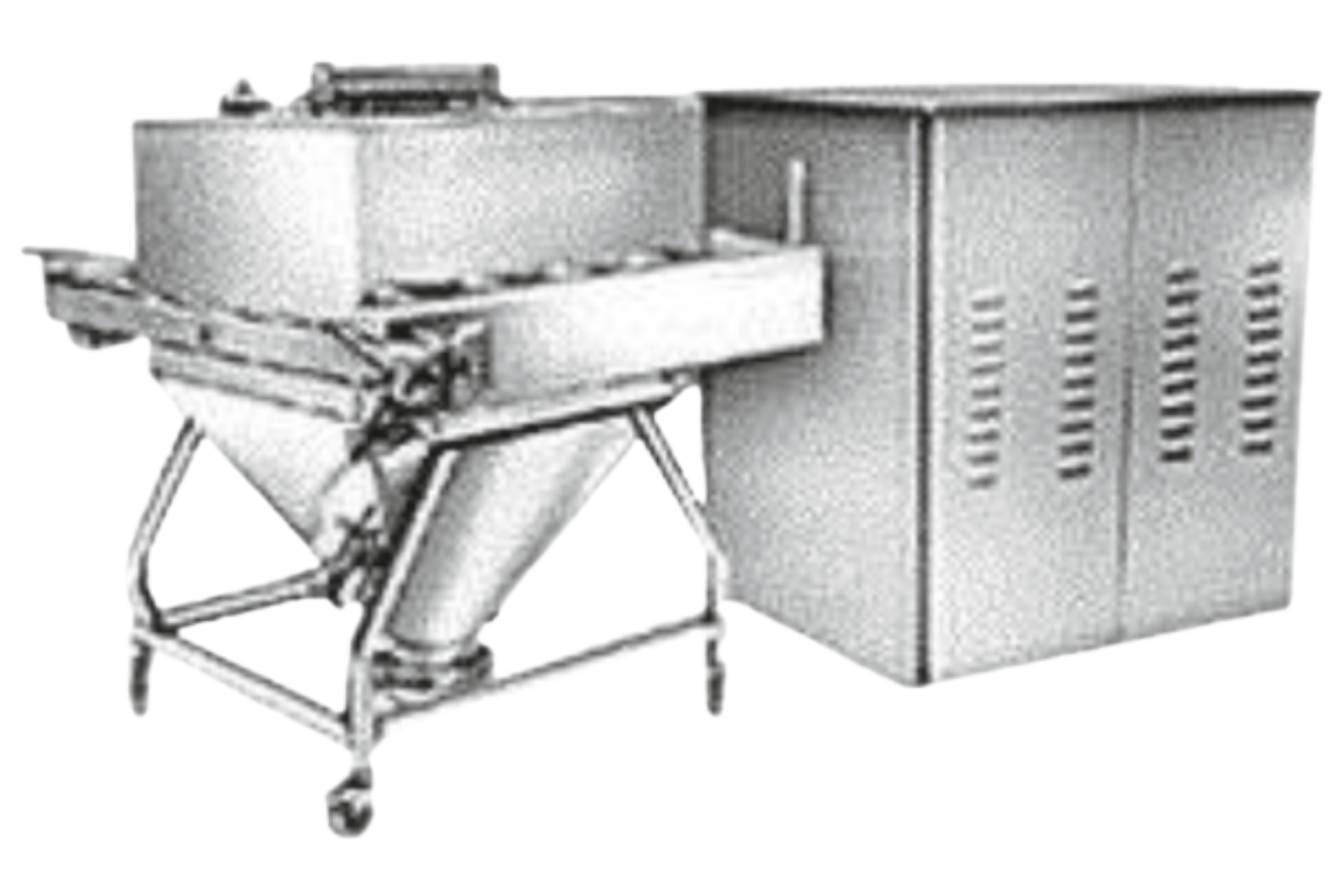

ROTARY CONE VACUUM DRYER

Available in 15 Lts. To 3000 Lts.

Available STD/GMP & Lab Model.

Contact parts SS 316 & Non Contact parts SS 304.

Condenser and Receiver.

PLC can be provided (Optional).

FLP Electrical can be provided (Optional).

📌 What Is a Rotary Cone Vacuum Dryer (RCVD)

A Rotary Cone Vacuum Dryer is a batch drying system that gently dries heat-sensitive, volatile, or oxidizable materials under vacuum and at low temperatures. It’s widely used in pharmaceutical, chemical, food, and fine chemical industries for drying powders and wet cakes without damaging the product.

Why It’s Useful

Low temperature drying: Vacuum allows moisture evaporation at lower temperatures.

Uniform drying: Conical shape plus rotation ensures even heat transfer.

Gentle on product: Ideal for delicate solids like APIs and chemicals.

Efficient solvent recovery: Integrated vacuum & condenser systems help recover solvents.

🔍 Typical Specifications (General Industrial Range)

| Parameter | Typical Values / Range |

|---|---|

| Capacity (Gross) | 50 to 5000+ Litres (batch) |

| Working Volume | ~50–70 % of gross volume ( |

| Material of Construction (MOC) | SS 304 / SS 316 / optional Hastelloy, coatings ) |

| Heating Medium | Steam, hot water, hot oil jacket () |

| Operating Pressure | Vacuum up to ~760 mm Hg (full vacuum) ) |

| Temperature Range | ~35 °C to 100+ °C depending on product ) |

| Rotational Speed | ~3–15 RPM (slow tumble) ) |

| Motor Power | ~0.5 – 20 HP or more (depends on size) |

| Construction Standard | cGMP, ASME, FDA compliant options available ( |

| Additional Options | PLC/HMI automation, lump breakers, nitrogen purge |

🧰 Key Functional Features

Design & Operation

Conical vessel rotates slowly under vacuum to tumble the product.

Jacketed surface provides indirect heat transfer.

Minimal internal parts reduces contamination and simplifies cleaning.

Benefits

✔ Uniform drying with reduced hot spots

✔ Shorter drying time than static dryers

✔ Near-complete discharge with cone shape

✔ Suitable for volatile & toxic materials

Common Options

Integrated solvent condenser & receiver

Vacuum pump system

PLC/fully automated control

🏭 Typical Uses

Drying wet cake after filtration (pharma & chemicals)

Handling heat-sensitive APIs & intermediates

Food additives, dyes, catalysts, pigments